BRENDLORENZEN WATERWORKS

Removal of iron and acid

from drinking water

The old waterworks ceased operations with the construction and launch of the new Brendlorenzen / Bad Neustadt a.d. Saale Waterworks at the end of 2019.

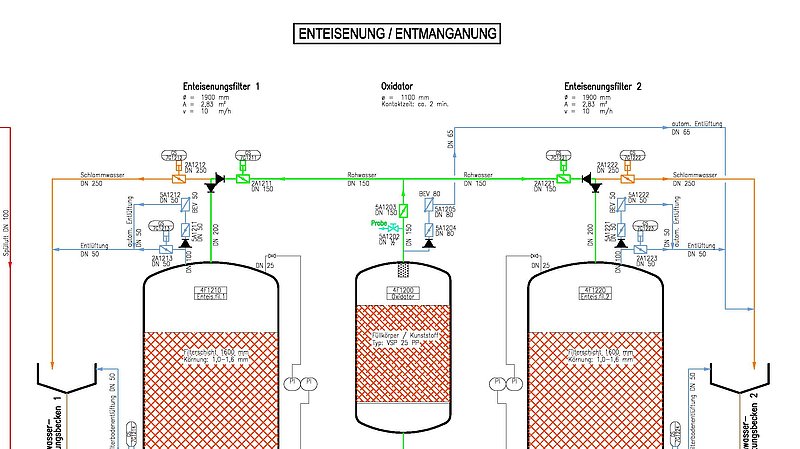

In the new waterworks, untreated water pumped to the processing building by frequency-controlled submersible pumps is first given oxidation air, and then fed to a packed bed oxidizer in which the air and water are thoroughly mixed together. In two parallel downstream sand filters iron and manganese are oxidized and filtered out of the water.

The filtrate passes through a UV unit for disinfection, then flows into two parallel flatbed aerators (physical deacidification unit), where air is blown in to drive out excess carbon dioxide and bring the water into a harmless condition from the standpoint of corrosion chemistry.

The deacidified water then flows directly into two clean water tanks. These clean water tanks are, at the same time, elevated tanks from which the local grid of Brendlorenzen is supplied with drinking water. They also serve as rinse water containers for backwashing of the filters and the oxidator.

With the help of an appropriate measurement, regulation, and control equipment, the entire waterworks is operated fully automatically. Any fault messages are transmitted remotely to the operator.

DATA

Treatment capacity:

up to 54 m³/h

PROCESS ENGINEERING

- Well technology

- Packed bed oxidizer

- Iron removal filters

- UV units

- Physical deacidification

- Clean water tanks

RESULT

Sanitized drinking water with iron

and manganese values below the

required limits

Rinsing pumps

Oxidator and Iron removal filters

UV units

Flatbed aerator